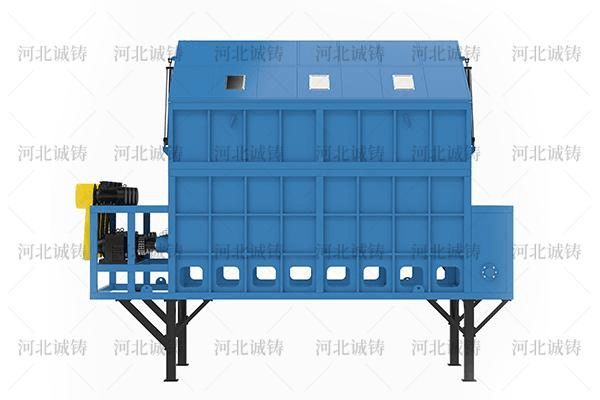

Raw material bin原料仓

原料仓是一种通用性较强的喂料输送机械,动力采用减速电动机驱动,料仓盖气缸控制,抽拉式;料仓底部设有三轴或四轴螺旋输送,每根螺旋输送单独控制及自动单独循环控制;可作为物料储存与输送,具有操作简单,使用方便,用途广泛特点。

Raw material bin is a general-purpose feeding and conveying machinery, the power is driven by a deceleration motor, the cover cylinder control, pull-out type; bin bottom with three-axis or four-axis screw conveyor, each screw conveyor separate control and automatic separate cycle control; can be used as a material storage and conveying, with simple operation, easy to use, and wide range of uses characteristics.

原料仓的主要结构The main structure of the raw material bin:

本机由主体框架、主喂料箱体、附喂料箱体、仓盖、螺旋主轴、连体出料螺旋输送机、电动机、减速机、摆线针减速机、链轮联接器、及电气等组成。整机结构紧凑,工艺合理。

The machine consists of main frame, main feeding box, attached feeding box, bin cover, screw spindle, connected discharge screw conveyor, motor, reducer, cycloid reducer, sprocket coupler, and electrical components. The whole machine has compact structure and reasonable technology.

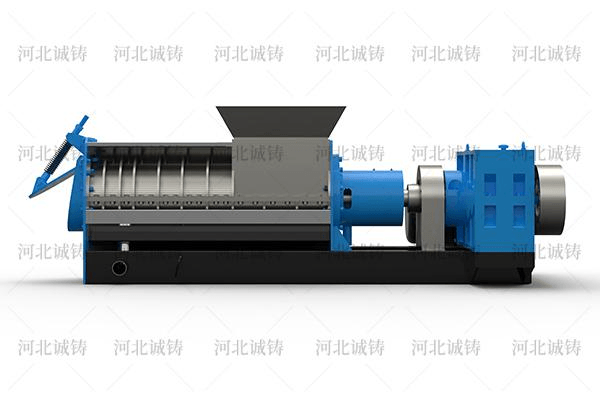

电动机启动时通过三角带传动减速机及联接器带动螺旋主轴运转,同时能控制主轴倒顺运转。连体出料螺旋输送机摆线针减速机启动通过链轮链条带动主轴运转。

The motor starts to drive the screw spindle through the triangle belt drive reducer and coupler, and at the same time, it can control the spindle to run upside down. Siamese discharging screw conveyor cycloid reducer starts to drive the main shaft through the sprocket chain.

原料仓的主要设计The main design:

仓门:仓门配备电控气动系统,可设置为自动化开启仓门方便快捷的收集原料,原料收集完毕自动化关闭,

减少气味外泄,提高卫生标准。

Door: the door is equipped with an electronically controlled pneumatic system, which can be set to automate the opening of the door for convenient and quick collection of raw materials, and automated closing of the raw materials after collection.

Reduce odor leakage and improve hygiene standard.

仓体:原料仓的仓体材质为不锈钢、碳钢,具有高硬度和耐磨性的优点。碳钢通常比普通钢铁硬度更高,更耐磨。

原料仓壳体表面附有耐腐蚀涂层减少氧化及腐蚀,延长使用寿命。

Bin body: The material of the body of the raw material bin is stainless steel and carbon steel, which has the advantages of high hardness and wear resistance. Carbon steel is usually harder than ordinary steel, more wear-resistant.

Raw material bin shell surface with corrosion-resistant coating to reduce oxidation and corrosion, to extend the service life.

原料仓的壳体还可以根据不同的情况选用不同的材料,如:不锈钢,特殊硬质合金等。以应对不同的使用情况。

The shell of the raw material bin can also choose different materials according to different situations, such as: stainless steel, special hard alloy and so on. To cope with different use cases.

仓底:原料仓的仓底装有螺旋输送机,对收集的物料进行稳定高效的输送,提高生产效率,防止物料堆积。

仓底的螺旋输送机装有电控组件根据生产时的不同情况调整物料的输送速度达到,加快输送,缓慢输送,

停止输送的功能。

Bottom of the bin: The bottom of the raw material bin is equipped with a screw conveyor, which provides stable and efficient transportation of the collected materials, improves the production efficiency and prevents the accumulation of materials.

The screw conveyor at the bottom of the bin is equipped with electric control components to adjust the conveying speed of the materials according to the different conditions of production to achieve the function of speeding up the conveying, slowing down the conveying, and stopping the conveying.

我们的型号Model:

型号

容积

材质

电机功率

CZYL-15

15m3

碳钢

7.5*3 kw

CZYL-20

20m3

碳钢

11*4 kw

原料仓可依据客户不同的生产情况,为客户生产不同容积,不同材质的原料仓。

Raw material bin can be produced with different volumes and materials according to the different production conditions of customers.

服务热线

服务热线