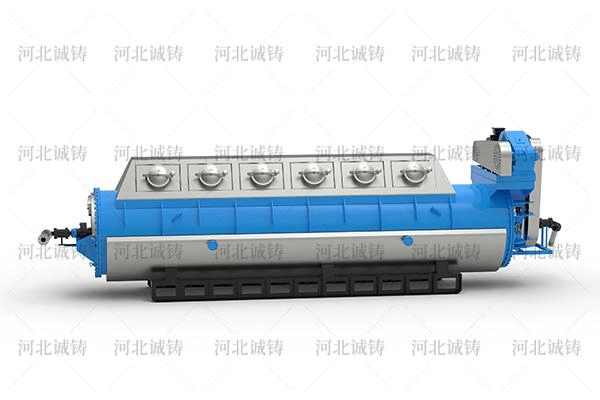

Cooker化制机

在动物无害化,屠宰废弃物处理中,化制机是一种常用的设备,用于处理动物尸体或者畜禽屠宰过程中产生的副产品。

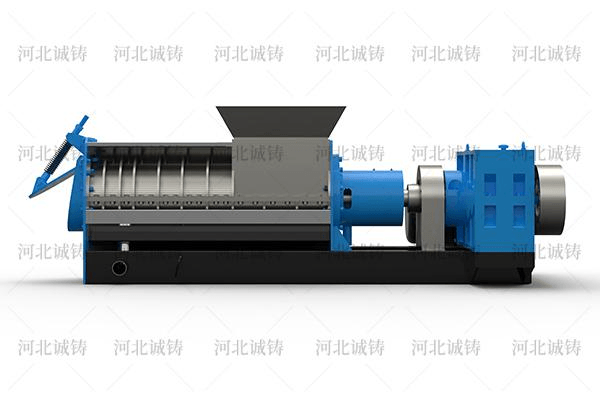

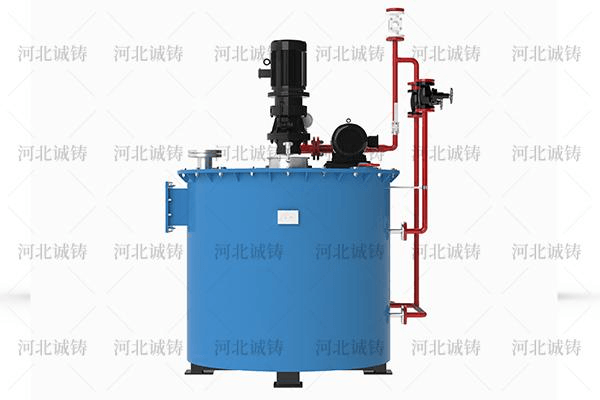

工作原理: 原料进入化制机内常温水解30分钟后,加盖密封使原料温度达到140度,以杀灭大肠杆菌,打破角质蛋白分子,工作压力达到0.3MPa后保持15分钟,排出罐内蒸气。继续加热20分钟后进入真空烘干,直至烘干到要求水分。

Cooker is a commonly used equipment for the treatment of animal carcasses or by-products produced in the process of animal slaughtering ,in animal and slaughtering waste harmless treatment.

Working Principle: After the raw material is hydrolyzed at room temperature for 30 minutes in the cooker, the lid is sealed to make the raw material temperature reach 140 degrees to kill E. coli and break the keratin molecules, the working pressure reaches 0.3MPa and then keep it for 15 minutes, and then discharged the steam in the tank. Continue to heat for 20 minutes into the vacuum drying, until drying to the required moisture.

化制机在动物无害化,屠宰废弃物处理中具有以下应用:

The cooker has the following applications in the animal and slaughter waste rendering:

动物渣滓处理:化制机可以处理动物尸体或者畜禽屠宰过程中产生的渣滓、内脏、骨头等废弃物,将其加热蒸煮后,分解成肉骨粉、油脂或者有机肥原料。

Animal residue treatment: the cooker can deal with animal carcasses or animal and poultry slaughtering process of residue, viscera, bones and other waste, will be heated and boiled, decomposed into meat and bone powder, grease or organic fertilizer raw materials.

优势和特点Advantages and features:

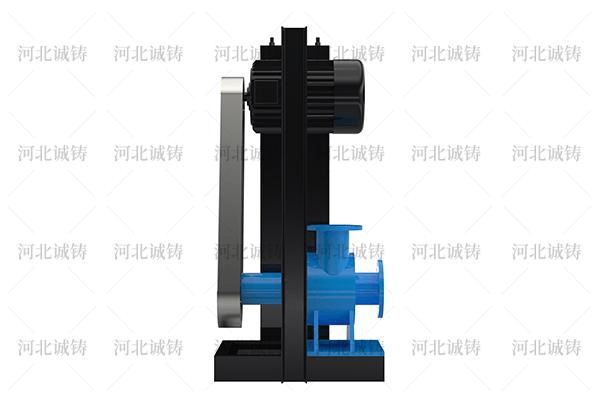

优点;具有结构紧凑、耐高温、传动平稳、噪声低安装简便、维修方便、运行可靠、节约能源等优点。

Advantages; has a compact structure, high temperature resistance, smooth transmission, low noise easy installation, easy maintenance, reliable operation, energy saving and other advantages.

消毒处理:化制机能够高温高压地处理废弃物,有效杀灭细菌和病毒,减少环境污染和传染病的传播风险。

Disinfection: The cooker is capable of treating waste at high temperatures and pressures, effectively killing bacteria and viruses and reducing the risk of environmental pollution and the spread of infectious diseases.

资源回收:通过化制机处理废弃物,可以将其转化为肉骨粉、油脂、有机肥料等可再利用的产品,

实现资源的回收和再利用。

Resource Recovery: By treating the waste through the cooker, it can be converted into reusable products such as meat and bone meal, oil and fat, organic fertilizer, etc., to

Realize the recovery and reuse of resources.

高效性:化制机通常具有高加工效率和处理能力,适用于各种禽类羽毛、动物皮毛、动物骨骼、内脏、碎肉、肠衣及内留物通过高温、高压、灭菌做成羽毛粉、肉骨粉等。

High efficiency: The cooker usually has high processing efficiency and processing capacity, which is suitable for all kinds of poultry feathers, animal hides and skins, animal bones, offal, minced meat, intestines and inner residues to be made into feather meal, meat and bone meal through high temperature, high pressure and sterilizing.

精确控制:通过控制加热温度、压力和时间等参数,可以实现对加工过程的精确控制,以满足不同产品的需求。

Precise control: By controlling parameters such as heating temperature, pressure and time, precise control of the process can be realized to meet the needs of different products.

可靠性:化制机通常具有坚固耐用的设计,能够在长时间运行和恶劣环境下工作。

Reliability: Cookers typically have a rugged design that is capable of operating over long periods of time and in harsh environments.

自动化:化制机可以与自动化系统集成,实现自动控制和监测,提高操作便利性和效率。

Automation: The cooker can be integrated with automation systems for automatic control and monitoring, improving ease of operation and efficiency.

我们的型号Model:

型号

内径

长度

容积

动力

换热面积

耗气量

运输尺寸

运输重量

CZHZ-1600-8

1600 mm

5000 mm

8 m3

55 kw

44.2㎡

1500-1800 kg/h

7500*1900*2400 mm

16500 kg

CZHZ-1800-14

1800mm

7000mm

14m3

75 kw

71.4㎡

1800-2200kg/h

10000*2140*2600

28000kg

设备根据客户不同的需求提供不同型号的设备。

The equipment is available in different models according to the different needs of customers.

服务热线

服务热线