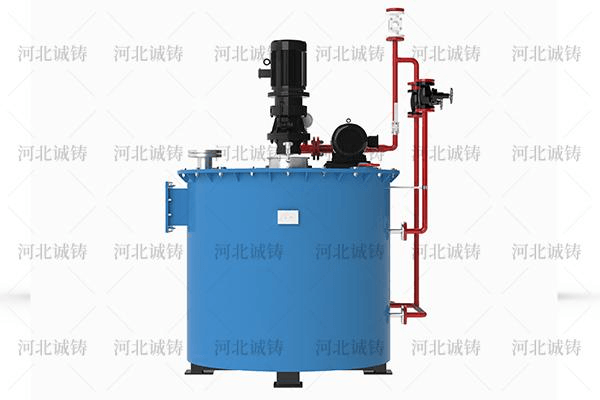

Hydrolyzer水解罐

水解罐是一种用于羽毛处理的设备,主要用于将羽毛进行水解处理,以提取出其中的蛋白质和其他有价值的成分。

A hydrolyzer is a device used for feather processing, which is mainly used to hydrolyze feathers to extract proteins and other valuable components from them.

水解罐的工作原理:

Principle of operation

原料进入水解罐内,加盖密封使罐内温度达到140度,以杀灭大肠杆菌,打破角质蛋白分子,工作压力达到0.3MPa-0.45MPA后保持15分钟,排出罐内蒸气。

Raw materials into the hydrolyzer, seal the lid so that the temperature inside the tank reaches 140 degrees, in order to kill Escherichia coli, to break the keratin molecules, the working pressure reaches 0.3MPa-0.45MPA after keeping 15 minutes, discharging the steam in the tank.

羽毛水解罐的主要设计:

The main design of the feather hydrolyzer

罐体:罐体是一个密封的容器,由耐高温和耐压的材料制成,以承受高温和压力的作用。

Tank: A tank is a sealed container made of heat and pressure resistant materials to withstand the effects of heat and pressure.

加热系统:加热系统用于提供高温(135~200 度),使用蒸汽来加热罐体。高温有助于加速水解反应的进行。

Heating System: The heating system is used to provide high temperatures (135 to 200 degrees) and uses steam to heat the tank. The high temperature helps to accelerate the hydrolysis reaction.

压力控制系统:压力控制系统用于控制罐体内的压力,确保在水解过程中保持适当的压力条件(0.5~0.7MPa)。

这有助于提高水解效率和产品质量。

Pressure control system: The pressure control system is used to control the pressure inside the tank to ensure that proper pressure conditions (0.5~0.7MPa) are maintained during the hydrolysis process.

This helps to improve hydrolysis efficiency and product quality.

羽毛水解罐的应用主要集中在饲料行业。在饲料行业,水解后的羽毛可以作为一种高蛋白质的饲料添加剂,用于提高动物的营养价值。

The application of feather hydrolysis tank is mainly focused on the feed industry. In the feed industry, hydrolyzed feathers can be used as a high protein feed additive for improving the nutritional value of animals.

在使用羽毛水解罐时,应该控制好水解的温度、时间和压力,以确保水解反应的效果和产品质量。同时,还需要进行废液和废气的处理,以避免对环境造成污染。

When using feather hydrolysis tank, the temperature, time and pressure of hydrolysis should be controlled to ensure the effect of hydrolysis reaction and product quality. At the same time, it is also necessary to carry out the treatment of waste liquid and waste gas in order to avoid pollution to the environment.

羽毛水解罐的优点Advantages:

提取有价值成分:羽毛中含有丰富的蛋白质和其他有价值的成分,通过水解罐的处理,可以有效地提取出这些成分。

这些提取出的成分可作为饲料添加剂,提高产品的营养价值。

Extraction of valuable components: Feathers are rich in proteins and other valuable components, which can be effectively extracted through the treatment of hydrolysis tanks.

These extracted components can be used as feed additives to improve the nutritional value of the product.

资源利用:羽毛通常是副产品或废弃物,通过水解罐的处理,可以将其转化为有用的产品。

这有助于提高资源的利用效率,减少浪费。

Resource utilization: Feathers are often a by-product or waste product that can be converted into a useful product through treatment in a hydrolysis tank.

This helps to increase the efficiency of resource utilization and reduce waste.

提高产品质量:水解后的羽毛制作的羽毛粉蛋白质可以被分解成更小的肽链和氨基酸,

提高了蛋白质的可利用性和消化吸收率。这使得水解羽毛粉成为一种优质的蛋白质来源,

可用于动物饲料和水产料领域。

Improve product quality: the protein of feather meal made from hydrolyzed feathers can be broken down into smaller peptide chains and amino acids, which

This improves the availability and digestibility of the protein. This makes hydrolyzed feather meal a high-quality protein source that can be used in animal feed and aquatic feed.

It can be used in animal feed and aquaculture applications.

提高生产效率:羽毛水解罐通常具有自动化控制系统,可以对温度、时间和压力等参数进行精确控制,

提高水解反应的效率和稳定性。这有助于提高生产效率和产品的一致性。

Improve production efficiency: Feather hydrolysis tanks usually have an automated control system, which allows precise control of parameters such as temperature, time and pressure.

Improve the efficiency and stability of the hydrolysis reaction. This helps to improve productivity and product consistency.

羽毛水解罐是一种用于羽毛处理的设备,通过水解羽毛中的蛋白质,可以提取出有价值的成分,它在提高产品质量和资源利用方面具有重要的作用。

Feather hydrolyzer is a kind of equipment used for feather treatment, by hydrolyzing the proteins in feathers, valuable components can be extracted, it has an important role in improving product quality and resource utilization.

我们的型号Model:

型号

内径φmm

长度

mm

容积

m3

动力

kw

换热面积㎡

耗气量

kg/h

运输尺寸

mm

运输重量 kg

CZSJ-1400-6

1400

4500

6

37

27.8

600-800

7900*1760*2100

11000

CZSJ-1600-8

1600

5000

8

55

38.1

1200-1400

8710*1950*2150

16500

CZSJ-1800-12

1800

6000

12

55

55.9

1400-1900

9000*2450*2420

22500

CZSJ-1800-14

1800

7000

14

55

62.8

1600-2000

10120*2500*2440

26000

服务热线

服务热线